VPT is a global provider of critical power conversion solutions for avionics, military, and space applications.

VPT is part of the HEICO Electronics Technologies Group (NYSE:HEI.A) (NYSE: HEI). HEICO’s customers include a majority of the world’s airlines and airmotives, as well as numerous defence and space contractors.

Avionics and military DC-DC converters

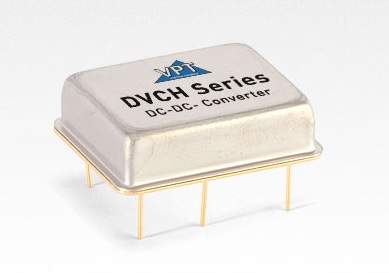

VPT’s isolated DC-DC converters, along with its family of non-isolated, synchronous, buck regulated, point-of-load DC-DC converters create an efficient and cost-effective power system for saving electronic board space, weight and heat.

VPT offers product lines that are ideal for military aircraft, weapons systems and unmanned systems.

With a wide variety of power conversion products, high efficiencies, wide temperature ranges and DLA Standard Microcircuit Drawings (SMDs) for most models, it is easy to match VPT’s power conversion products to a programme’s military specifications.

Ranging from 1w to 120w with a military temperature range of -55°C to 125°C, VPT’s DV series of products are proven in military and avionics applications. They are designed to meet rigid military specifications and 100% hermetic with a host of circuit protection features.

High-reliability rugged power DC-DC converters

VPT’s VXR series of rugged high-reliability DC-DC converters and electromagnetic interference (EMI) filters are optimised for a broad range of applications. These include military ground vehicles, manned and unmanned aircraft that endure severe vibration, shock, temperature cycling and other adverse environments.

Furthermore, VPT’s patented epoxy encapsulated V-SHIELD® packaging is also highly resistant to chemical, solvent and salt environments, making it fully compatible with high-volume manufacturing processes such as wave solder, cleaning solvents, high-pressure sprays and aqueous wash.

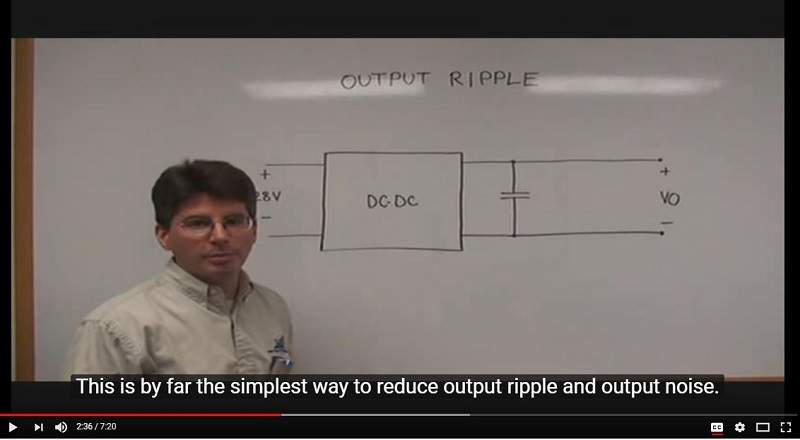

Advanced power conversion technology benefits

VPT’s continual advancements in power conversion technology deliver many unique advantages across its product lines, including:

- Maximum reliability, thick-film, hybrid technology

- Innovative, rugged, high-reliability architecture

- Proprietary epoxy encapsulation package availability

- Full operation over wide temperature ranges

- Excellent EMI performance

- High-power densities

- Lightweight

Rugged environmental screening

Each VPT product line offers several grades of environmental screening.

Depending on the product series selected, possible tests performed include:

- Non-destructive bond pull

- External and internal visual: constant acceleration and radiography

- Particle impact noise detection (PIND)

- Stabilisation bake and temperature cycling

- Electrical: pre burn-in electrical, burn-in and 100% final electrical

- Hermeticity

Efficient critical power system deployment

VPT understands the urgency of many programme timelines. The company maintains industry-leading stock levels, allowing immediate shipment, fast delivery and short turnaround times.

About VPT

VPT has been supplying high-reliability power converters to world-class organisations and programmes for more than two decades.

VPT products are included in military avionics programmes such as the F-15/16/18/22 and F35, the Watchkeeper UAV, Blackhawk Helicopter, EuroHawk UAV, Apache Helicopter, P-1 Aircraft and the Tornado Fighter.

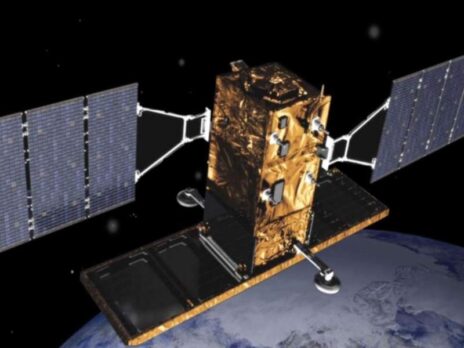

The company’s strong heritage in space solutions includes the International Space Station, Pluto New Horizons, Worldview-3 satellite system, Atlas V, and ExoMars.